Introduction:

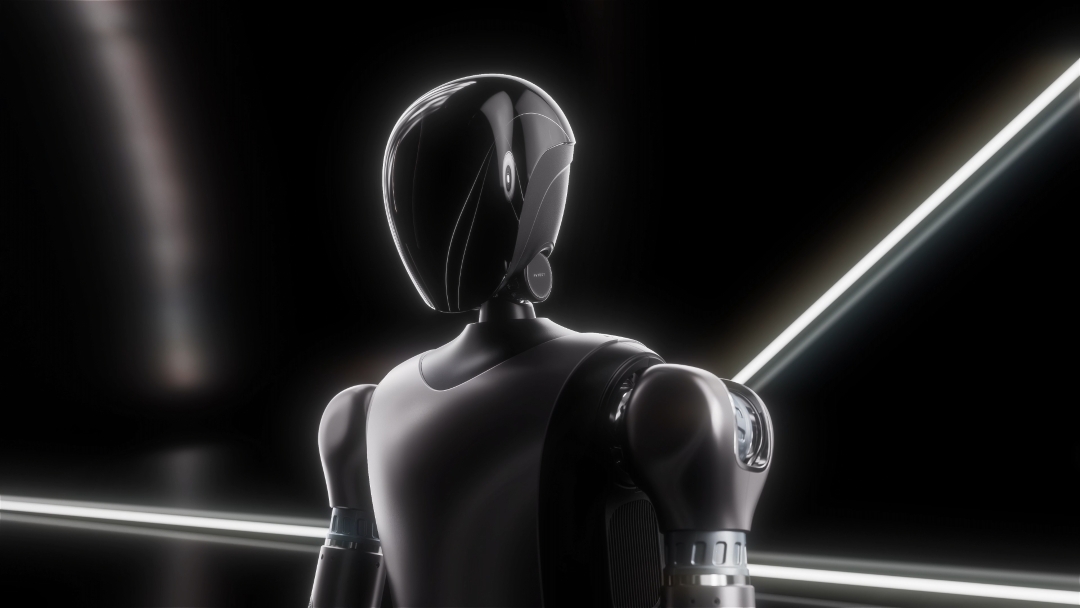

History is being rewritten. The PHYBOT M1—a near 1.8m, 70kg all-electric humanoid —has flawlessly executed a human-like backflip, marking a leap into the "superhuman" robotics era.

For PHYBOT, technical peaks set the ceiling for the industry. The move wasn’t just spectacle: it tested the core limits of superhuman capability—extreme balance, >10kW instant power, precise body coordination. Only by mastering human physicality feats on an adult-scale bot can hardware, actuation and controls prove they can replace or even surpass human labor in tough, high-intensity settings. M1’s flip is both a stress test and a proof of "the most powerful new productivity tool.

In recent years, most humanoid robots displaying high-dynamic motions use small or medium bodies —smaller size eases inertia and center-of-mass control, as seen in PHYBOT’s Phybot C1.

Large humanoids face specific issues: large inertia, low joint torque, and poor gait control cause instability, highlighting the unresolved "power-structure-control" balance.

As a result, combining "strong mobility" and "full-scale" application is hard. Smaller builds face lower joint torque and energy demands; larger ones require far higher torque, energy density, and durability for similar performance. Truly near-adult-height (170cm+) yet highly mobile, powerful platforms remain rare.

From Dynamic Walking to Dynamic Motion: Humanoid Robots Break New Boundaries

PHYBOT M1

PHYBOT M1, adult-sized and developed entirely in-house, displays electric actuation that now outperforms hydraulics in terms of dynamics. With a joint torque over 800 N·m and total power over 10,000W, it beats hydraulic systems in terms of both power and torque density (10 N·m/kg), while maintaining the electric benefits: precision, low back-drivability, fast response. It also leads in efficiency, control, noise, and maintenance, removing deployment limits.

The motor-reduction-lightweight synergy gives power margins rivaling smaller robots, enabling tasks to be expanded to include manufacturing, logistics, and emergencies. PHYBOT uses a lightweight base structure combined with actuation to boost stability and motion redundancy in unprotected large humanoids. Paired with end-to-end embodied AI, this enables real-time prediction, self-correction, and closed-loop motion control.

PHYBOT M1: Core Breakthrough into the New Era

Despite its size (~1.8m, ~70kg), performing extreme moves like backflips is still tough for PHYBOT M1:

High Inertia, Tight Control: Its mass demands ultra-fast drive response, high peak power, and precise control.

Sim-to-Real Gap: Real-world physics differ from models; even the smallest mismatches can cause failure.

Power vs. Safety: Releasing its 10kW burst power (idle ~200W) requires careful motion limits to prevent damage.

Tech Deep Dive: 3 Algorithms for High-Difficulty Maneuvers

Innovation 1: Acceleration-Constrained Trajectory Retargeting

Motion data often violates the rules of physics, hurting training with poor motion and use of force. PHYBOT’s method rescales unrealistic trajectories to fit physical limits, boosting RL tracking and aligning motions with large robot traits. Augmented retargeted data also adds trajectory variants; using using variance and mean as well as encoding and decoding and encoding or decoding ensures smooth posture shifts, improving generalization and robustness.

Innovation 2: Parameter ID-Based Domain Randomization

Large robots feature distinct inertia and damping. Standard domain randomization often misses real parameter ranges or harms the policy if overdone. The design team pre-identified key motor and body parameters parameters, then applied domain randomization around them, improving policy generalization and sim-to-real success.

Innovation 3: Two-Stage Training

Soft-constrained RL may breach limits near performance edges, risking hardware.

The team used two stages: first, the robot was trained in simulation for rough motion after which it was fine-tuned with low entropy and motor-limit terminations, enabling safe maximum performance.

Experimental Validation: From Simulation to Reality

Simulation: 100% success rate for backflips.

Reality: First stable backflip on a physical heavy-duty electric humanoid robot, with good disturbance rejection and self-recovery.

Significance:

More than a stunt—this marks a leap from walking to tumbling, surpassing hydraulic robots and highlighting electric design benefits.

Next Step: PHYBOT aims to push third-gen superhumanoid robots even further, raising industry limits and targeting multi-dimensional human-level performance.

PHYBOT believes technical innovation should serve extreme environments—tasks humans cannot or should not do. PHYBOT M1’s backflip proves that its platform balances dynamic control, explosive power and smart decisions, enabling it to outperform humans in complex settings. Committed to turning humanoid robots from lab demos into reliable industry tools, PHYBOT makes sci-fi a reality.

Company Website: www.phybot.tech

Media Contact

Company Name: Beijing Phybot Technology Co., Ltd

Contact Person: Aonian GONG

Email: Send Email

Country: China

Website: www.phybot.tech